Online sheet metal fabrication service

Your online sheet metal cutting and bending service. Upload your parts, get a free instant quote.

Our sheet metal fabrication capabilities

Debaolong Seiko gives you easy access to sheet metal fabrication capabilities to serve all your manufacturing needs.

FDM

- Fast & affordable prototyping

- Dimensional accuracy of ±0.5% with a lower limit: ± 0.5mm

- Lead times from 1 business day

SLS

- Functional prototyping &low-run production

- Dimensional accuracy of ±0.3% with a lower limit of ± 0.3mm(±0.012″)

- Lead times from 3 business

MJF

- Functional prototyping &low-run production

- Dimensional accuracy of ±0.3% with a lower limit of ± 0.3mm(±0.012”)

- Lead times from 3 business days

SLA

- Visual prototyping

- Dimensional accuracy of ±0.3% with a lower limit of ± 0.3mm(± 0.012”)

- Lead times from 2 business days

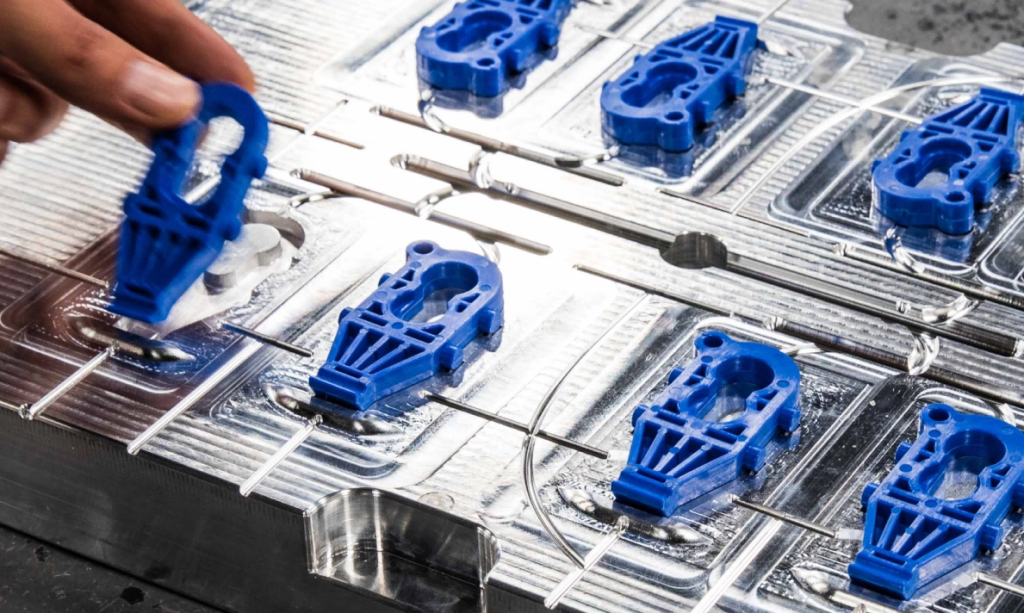

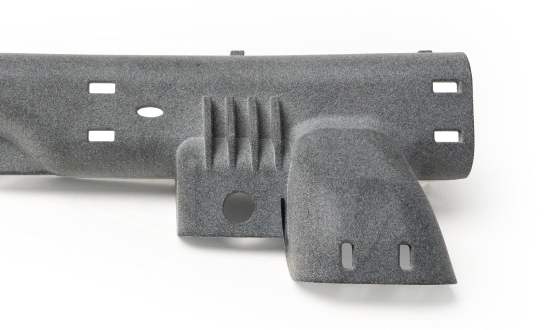

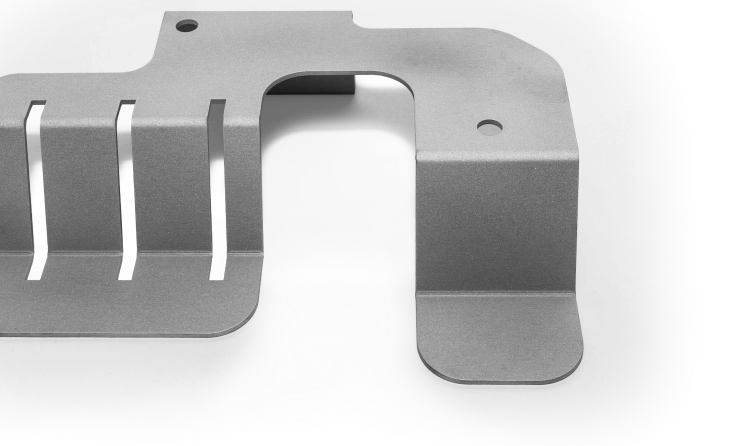

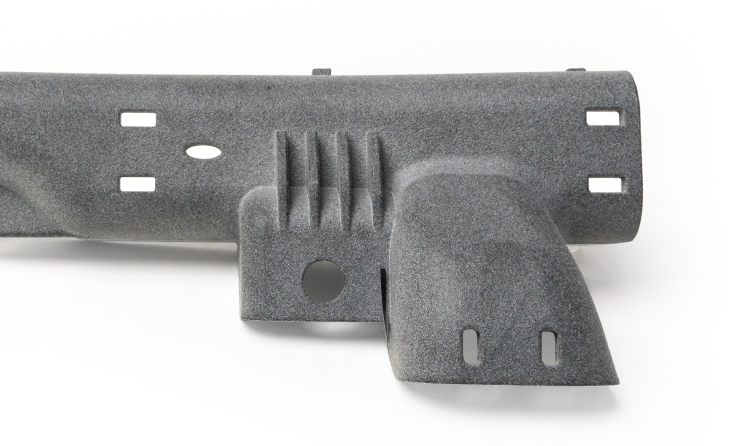

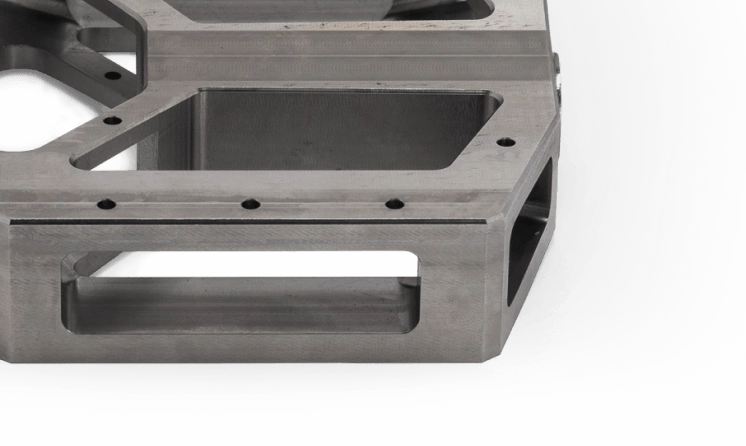

Gallery of Sheet Metal Parts

Here’s a small selection of the Sheet Metal prototypes and end-use parts we’ve produced for our customers.

CNC machining Part5

CNC machining Part4

CNC machining Part3

CNC machining Part2

CNC machining Part1

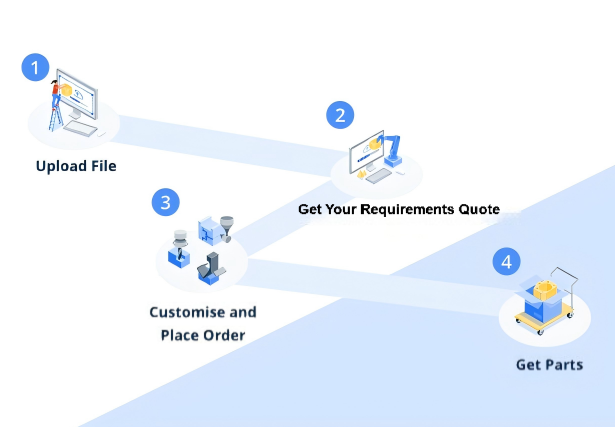

Quotation options

Diversified quotes, customers can upload drawings of parts that need to be customized.

- Customers can send drawings to Debaoloong@gmail.com or register on the website and upload your files.

- CAD drawings include (STEP, STP, IGES, IGS, SLDPRT, 3DM, PDF, SAT, or X_T)

- Please specify your requirements (material, quantity, delivery time)

- We will provide a quotation as soon as we receive your inquiry. The quotation will be sent to the email address you provided. Please check your email promptly.

Our ordering process

Debaolong Standard - consistent quality, every time

Debaolong Seiko takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets Debaolong Standard.

Inspection standards

Visual and dimensional inspection & defects

Dimensional accuracy

Sample measurements & general rules

Cosmetic standards

Standard offering & post-processing options

Specialist industries

We’ve manufactured millions of parts for all sorts of applications, but we’re especially knowledgeable in these areas.

Robotics & automation

Automotive

Industrial machinery

Aerospace & aviation

Our client network

Debaolong Seiko is dedicated to providing one-stop custom manufacturing services, including CNC machining, 3D printing, sheet metal fabrication, injection moulding, die casting, and mould making. Our services are widely recognised and trusted worldwide, with clients in Europe, the United States, Russia, Japan, and South Korea.

More resources for sheet metal fabrication

Learn more about how sheet metal fabrication works and how to design the best parts for this technology.

FAQ's about sheet metal fabrication service

What sheet metal fabrication processes do you offer?

We offer two types of sheet metal fabrication: laser cutting and bending. Laser cutting uses a high-power laser beam to cut a material sheet between 1 and 6mm thick, depending on the material. Bending uses dies to produce a u-shape, v-shape, or channel shape along a straight axis in ductile materials. It can work with metals 1-6mm thick.

What is the typical turnaround time for sheet metal fabrication projects?

The typical turnaround time for sheet metal fabrication varies depending on the metal’s thickness, design complexity and the number of parts you require. However, turnaround times generally start from five days.

What advanced technologies are used in your sheet metal fabrication processes?

Our sheet metal fabrication processes use advanced surface finishes to enhance part properties. These include bead blasting, brushing, anodizing (type II and III), powder coating, black oxide coating, and chromate conversion coating. These finishes improve corrosion and wear-resistance, surface texture, and appearance while maintaining conductive properties. All parts are deburred for safety to ensure quality and durability.