Source custom parts for industrial machinery

- Huge range of technologies and materials

- Fast and reliable with local and global manufacturing options

- All uploads are secure and confidential

Trusted by engineers at

Produce quality industrial machinery components

Debaolong Seiko can help you get to production faster without compromising design or quality. With our specialized manufacturing experiences, you can strengthen your supply chain and get customized parts for a wide range of prototyping, R&D, validation, and full production needs. With Debaolong Seiko’s cutting-edge capabilities and robust capacity, you can achieve your goals faster and accelerate innovation.

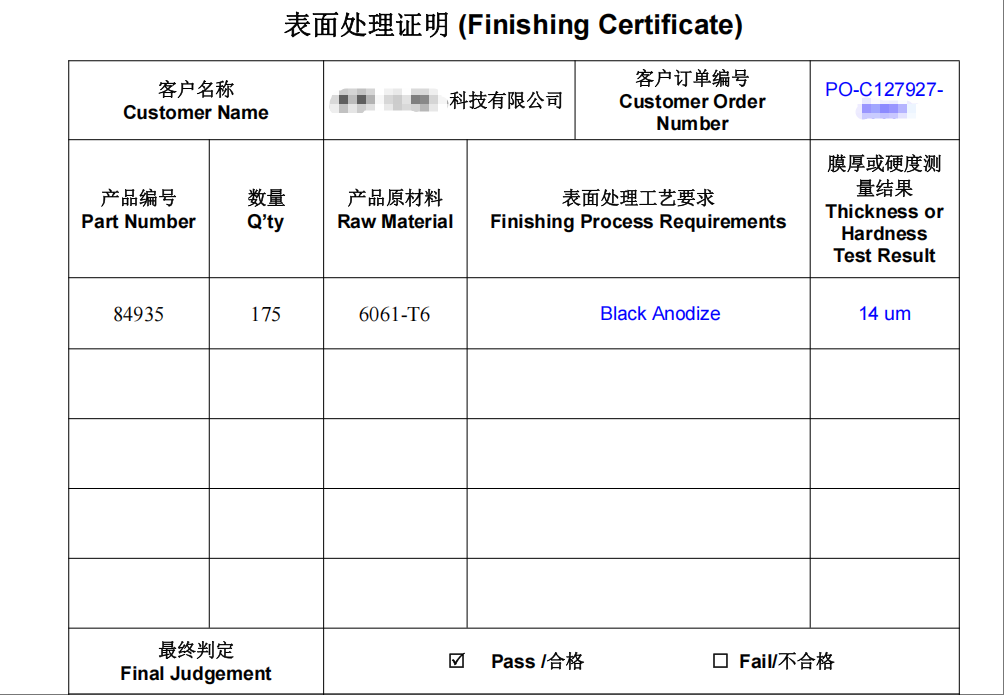

Selected Surface Finishes

Debaoloong Seiko has a complete production system, surface treatment report

Oxidize

Sandblast

Lacquer

Burnish

- Post-processing surface treatment of various products

See more about Finishes

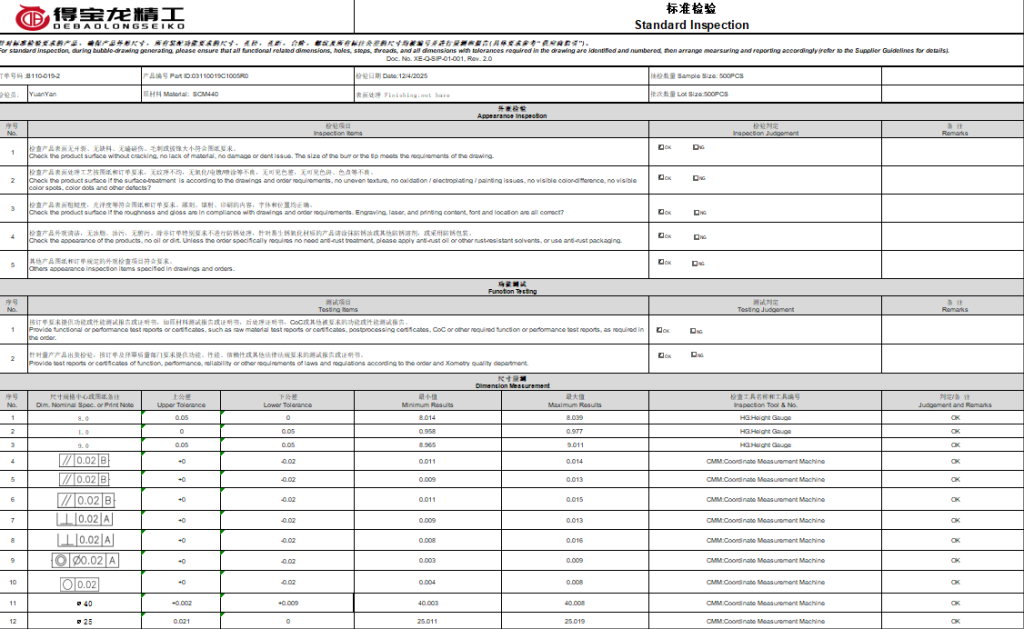

Comprehensive quality documentation

Get validation reports to ensure the highest quality and compliance.

CMM Inspection Report

Full Dimensional Inspections

Material Test Reports

Material Certificates

Certificates of Conformance

First Article Inspections

See all quality documentation

Highest quality standards

We use a rigorous set of protocols and procedures to maintain quality.

- Dimensional checks with calibrated equipment

Review of all quality documentation and industry certifications

Have perfect engineering management standard implementation

Read more about our quality standards

Parts in 1 day with Debaolong

Debaolong Seiko and its partners work together to provide you with the most comprehensive manufacturing solutions in the world. We offer a wide range of manufacturing capabilities and leverage the advantages of the Pearl River Delta region in China as the world’s technology manufacturing hub to enable rapid manufacturing and provide the shortest delivery times in the industry.

Get quick-turn parts with Debaolong

How industrial machinery work with Debaolong Seiko

- Moving parts

- Casings

- Conveyor belts

- Industrial jigs & fixtures

- Bearing

- Automation parts

- Replacement parts

- Prototyping

- Price estimates

- Housings

Industrial machinery manufacturing capabilities

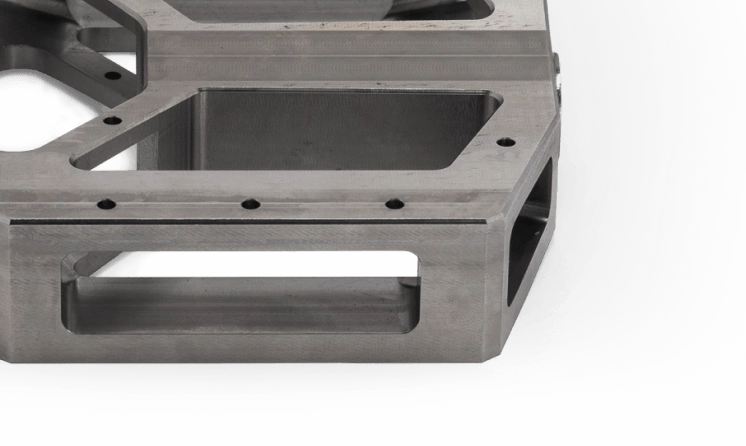

CNC machining

Milling, turning and post-processing

- Tolerances down to ±.020 mm (±.001 in)

- Lead times from 5 business days

See our CNC machining services

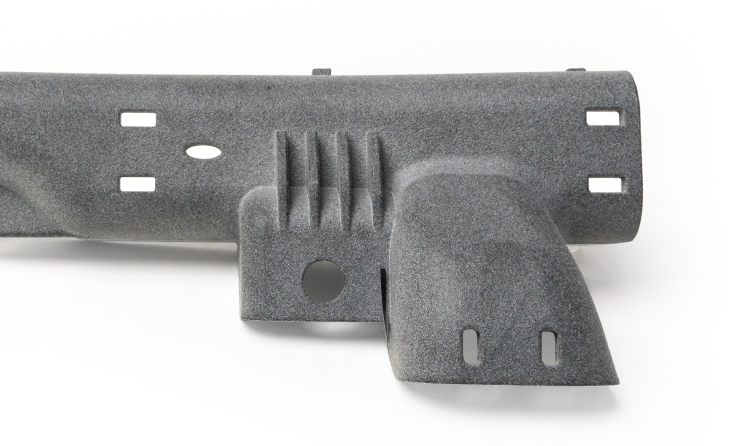

3D printing

FDM, SLA, SLS, MJF

- ± 0.3% with a lower limit of ± 0.3 mm (± 0.012 in)

- Lead times from 1 business day

See our 3D printing services

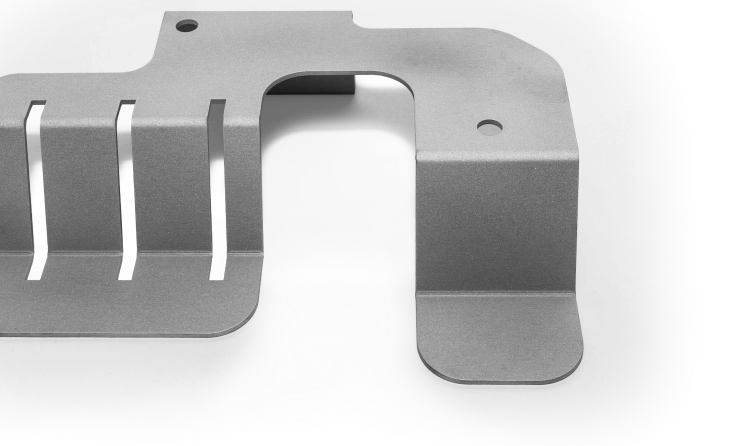

Sheet metal fabrication

Laser cutting, bending, post-processing

- Tolerances down to ±0.1 mm (±.004 in)

- Lead times from 5 business days

See our sheet metal fabrication services

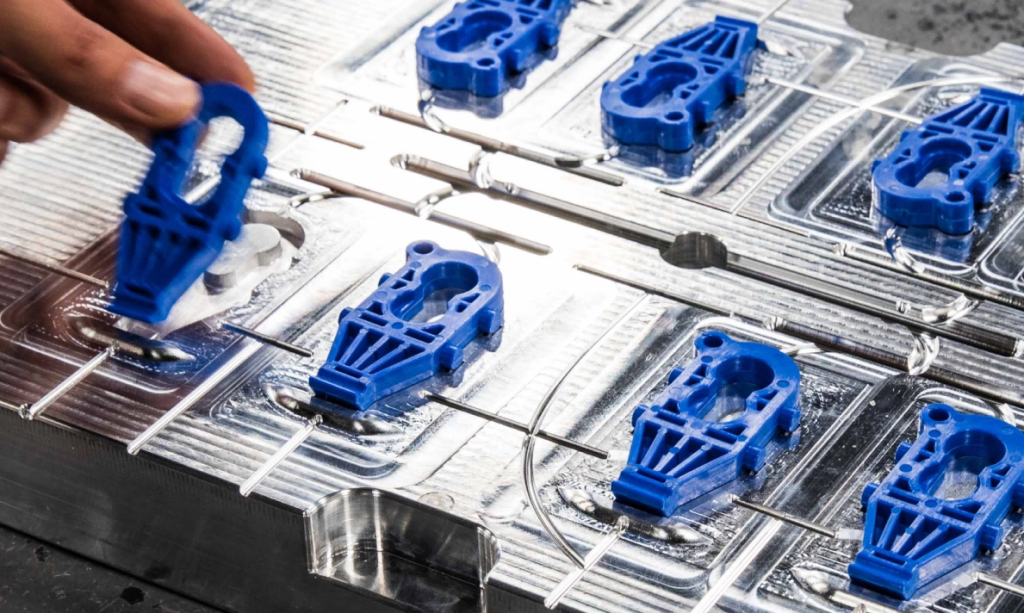

Injection molding

Prototypes and production tooling

- Wide range of part complexities and sizes

- 1 to 1M parts

See our injection molding capabilities

Why customers around the world choose Debaolong Seiko

Strong manufacturing chain

We are located in the manufacturing hub of China, with strong industrial support and a professional and experienced technical team.

Quality assurance

Every order comes with complete documentation, and the entire process from production to shipment is strictly controlled.

Quick Quotation

Get instant quotes with all pricing information upfront

How we help industrial machinery companies innovate

Competitive pricing and DFM guidance

The Debaolong Seiko is the easiest way to get competitive pricing for comparing order volumes, lead times, materials, tolerances, secondary processes, and more for your projects. Get all final pricing information upfront, including shipping, quality control and customs clearance .our mechanical engineers are always on hand to offer guidance to get the most out of Debaolong Seiko.

To spec and on time, every time

To keep your supply chain consistent and solid, we adhere to comprehensive quality control processes and protocols. Our production engineering controls are in accordance with international standards. Once production is complete the quality control team checks the functional and cosmetic specifications of the parts, and we handle all custom clearance requirements to ensure on-time delivery.

Source locally and globally

Debaolong Seiko not only serves customers in China, but the rest of the world is also important to us. We offer the most comprehensive range of industrial 3D printing, CNC machining services, injection molding, and sheet metal specialists, providing you with stable production capabilities, no matter how large or small your aerospace project is.