Online CNC machining service

Through Debaolong Seiko’s professional and experienced CNC machining center, we provide on-demand CNC machining services for rapid prototyping and production of parts.

Our CNC machining service capabilities

CNC machine all types of parts, from simple “as machined” workholdings to complex geometries. We operate almost every kind of CNC mill and turning center, with EDM and grinders available on request. We offer tolerances down to ±.020 mm (±.001 in) and lead times from 5 business days.

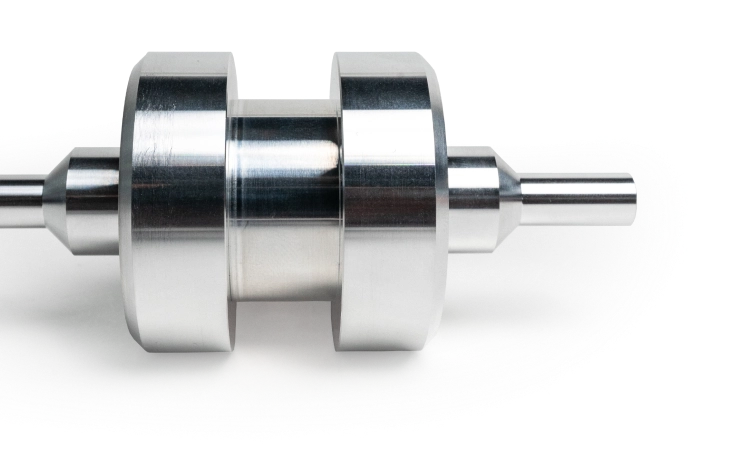

CNC turning

Access over 300 turning centers, including Swiss lathes and multi-axis mill turns.

3 & 5 axis CNC milling

Access over 1,000 milling centers, including standard 3-axis mills, indexed 3+2-axis mills & fully-continuous 5-axis mills

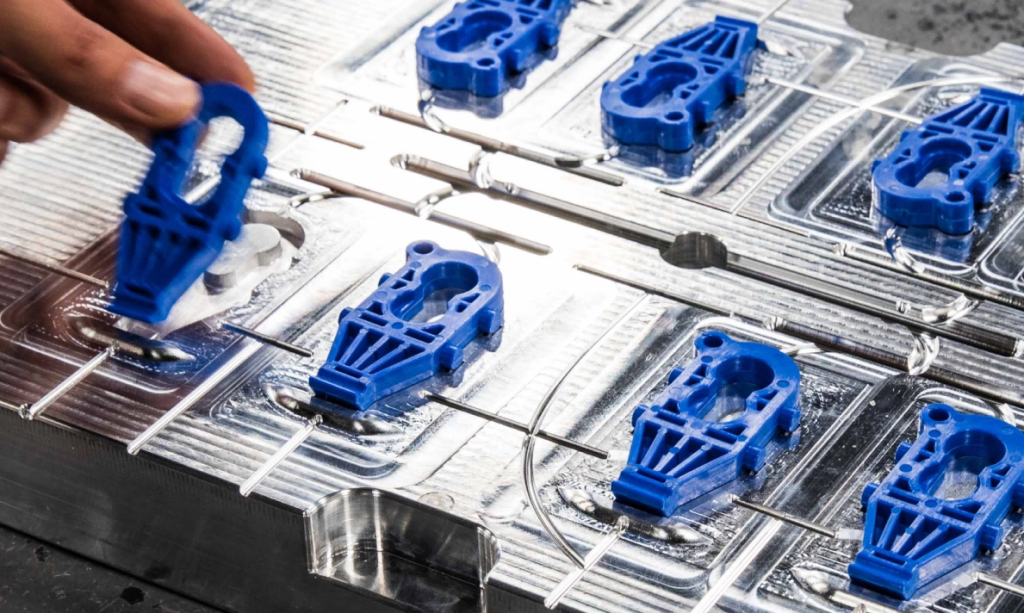

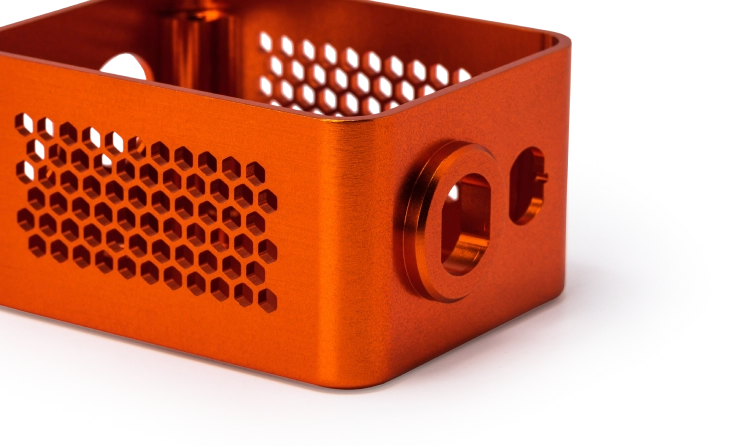

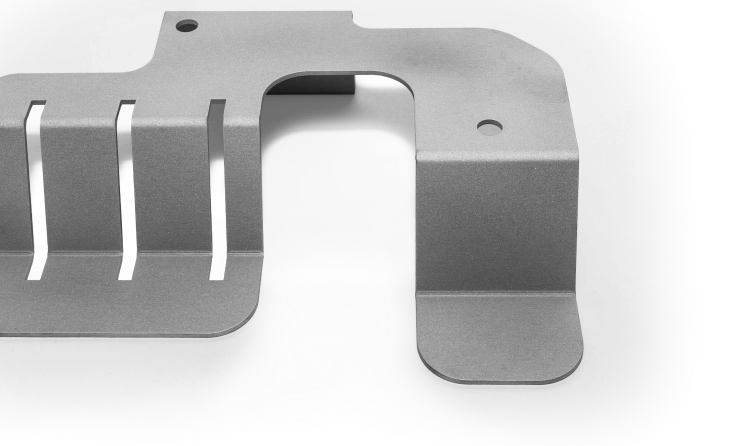

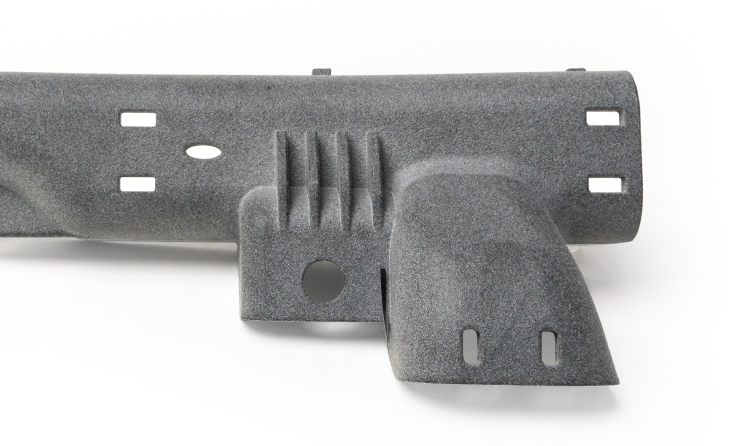

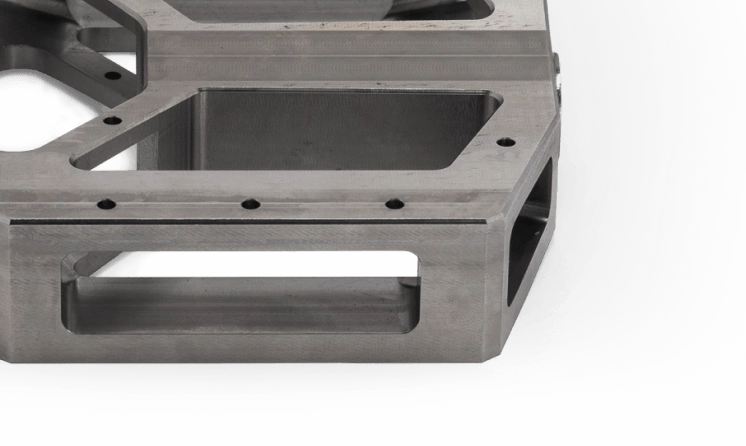

Gallery of CNC machined parts

Here’s a small selection of the CNC machined prototypes and end-use parts we’ve produced for our customers.

CNC machining Part5

CNC machining Part4

CNC machining Part3

CNC machining Part2

CNC machining Part1

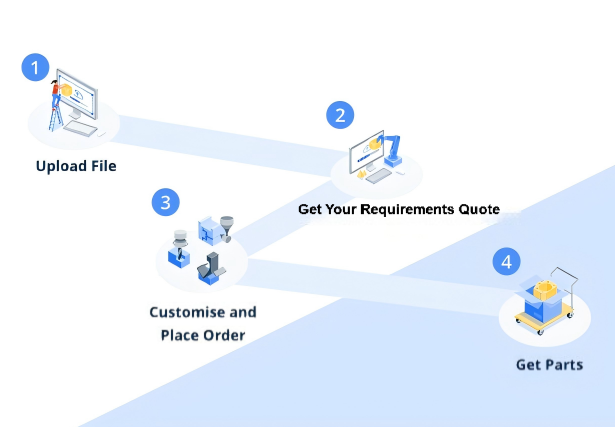

Quotation options

Diversified quotes, customers can upload drawings of parts that need to be customized.

- Customers can send drawings to Debaoloong@gmail.com or register on the website and upload your files.

- CAD drawings include (STEP, STP, IGES, IGS, SLDPRT, 3DM, PDF, SAT, or X_T)

- Please specify your requirements (material, quantity, delivery time)

- We will provide a quotation as soon as we receive your inquiry. The quotation will be sent to the email address you provided. Please check your email promptly.

Our ordering process

Debaolong Standard - consistent quality, every time

Debaolong Seiko takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets Debaolong Standard.

Inspection standards

Visual and dimensional inspection & defects

Dimensional accuracy

Sample measurements & general rules

Cosmetic standards

Standard offering & post-processing options

Specialist industries

We’ve manufactured millions of parts for all sorts of applications, but we’re especially knowledgeable in these areas.

Robotics & automation

Automotive

Industrial machinery

Aerospace & aviation

Our client network

Debaolong Seiko is dedicated to providing one-stop custom manufacturing services, including CNC machining, 3D printing, sheet metal fabrication, injection moulding, die casting, and mould making. Our services are widely recognised and trusted worldwide, with clients in Europe, the United States, Russia, Japan, and South Korea.

Features of our CNC machining centers

- As part of Debaolong's global service offering, we provide you with comprehensive manufacturing solutions from prototype to production. Here's what sets our machine shop apart

- We have an incredibly wide range of capabilities, far more than most machine shops. In most cases, we quote quickly in order to find the best solution for your project.

- From rapid prototyping with 1-day lead times to production of millions of parts in bulk, we can customize your order. We utilize China Industry's well-established supply chain system to ensure competitive pricing on every order.

- We machine custom parts for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil and gas, and robotics.

How we compare to traditional CNC machine shops

What tolerance standards do you guarantee?

We guarantee that our manufacturing follow ISO 2768 standards for all CNC machined parts. Parts machined with metal will follow ISO 2768-m (medium) or ISO 2768-f (fine). Parts machined with plastics will follow 2768-m (medium). Geometric tolerances down to ± 0004 in. (0.010 mm) are possible but must be clearly indicated in technical drawings. We can achieve tighter tolerances with manual quoting.

What are the minimum and maximum dimensions you can machine?

Debaolong Seiko offer CNC milling (3-axis, 3+2-axis and 5-axis) and turning. Milled parts can be machined up to 2000 x 1500 x 200 mm (78.7 x 59.0 x 7.8 in.) for 3/3+2 axis CNC milling. For 5-axis milling, the maximum part size is 650 x 650 x 300 mm (25.5 x 25.5 x 11.8 in.). The maximum diameter for CNC turning is 431mm (17 in.), length 990 mm (39 in). Minimum part dimensions recommended are around 0.39 x 0.39 x 0.39 in. (10 x 10 x 10mm).The minimum for feature dimensions is 0.5 mm.

We are limited to a 1000 mm (39 in.) maximum size for parts on our platform. If you need higher dimensions, you can place the request through your account manager.

How can I reduce the cost of my machined parts?

The main costs associated with CNC machining can be grouped into machining time, start-up costs, material costs, and feature costs. To reduce costs you need to understand the impact of these factors on cost.

The best way to reduce machining time is to design features that can be machined quickly, for example by choosing the correct radii for internal corners, reducing cavity depth, increasing wall thicknesses, limiting thread length and designing holes with standard sizes.

Material costs can be reduced by considering the size of the blank required, and the cost and machinability of the bulk material (softer alloys are faster to machine).

Start-up costs can be reduced by reducing the number part rotations or repositioning required to finish the part, for example by separating geometries into multiple parts that can be assembled later.

Feature costs can be reduced by only using tolerances when strictly necessary, removing all text & lettering, and avoiding multiple surface finishes.