Which 3D printing method will shape your ideas best? In this article, we’ll break down the key differences between FDM and SLA to help you decide.

What is FDM 3D printing?

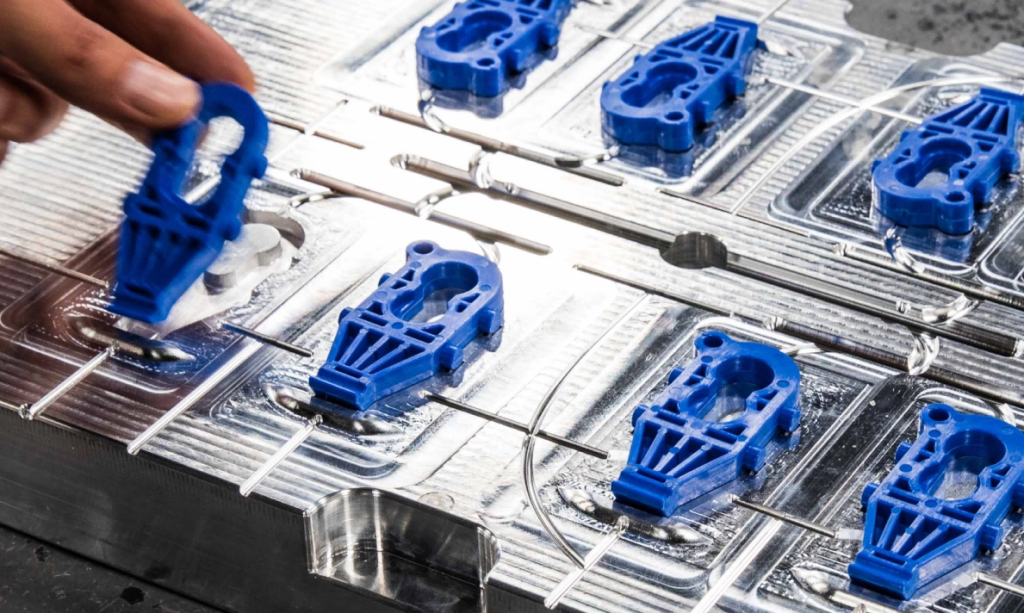

Fused Deposition Modeling (FDM) builds parts by melting thermoplastic filament and laying it down layer by layer. This method is simple and cost-effective, making it a favorite for both hobbyists and professionals. FDM is particularly effective for creating functional

prototypes, custom jigs, and durable end-use parts.

Materials used in FDM 3D printing

FDM 3D printing works with a wide range of thermoplastic filaments. Each one has different properties targeted to fulfill specific part requirements. Here’s an overview of some common options:

- ABS: Tough and impact-resistant.

- PLA: Biodegradable and easy to print, good for prototypes.

- PETG: Somewhere in between, combining the ease of PLA with the strength of ABS.

- Nylon: A durable and flexible choice for functional parts.

- Carbon-fiber blends: High strength and rigidity for demanding applications.

Learn more about FDM 3D printing materials. Advantages and disadvantages of FDM 3D printing FDM has its own set of strengths, weaknesses and trade-offs to weigh. Here’s a quick look at its pros and cons: Advantages

- Budget-friendly: Lower material and machine costs make it an economical choice.

- Quick turnaround: Faster print times, especially for larger parts.

- Material variety: A wide range of filaments available to meet different needs.

- Durability: Perfect for functional parts that need to last.

Disadvantages

- Visible layer lines: Post-processing may be needed for a smooth finish.

- Precision: Tolerances aren’t as tight as SLA.

- Post-processing: Support removal and smoothing might add extra steps.

What is SLA 3D printing?

Stereolithography (SLA) uses a laser to cure liquid resin into solid parts. It delivers smooth surface finishes and captures fine details. It’s the go-to process for applications like dental models, jewelry, and intricate prototypes where accuracy really matters.